Making Your Mark: When Ink was Made at Home, pt 1

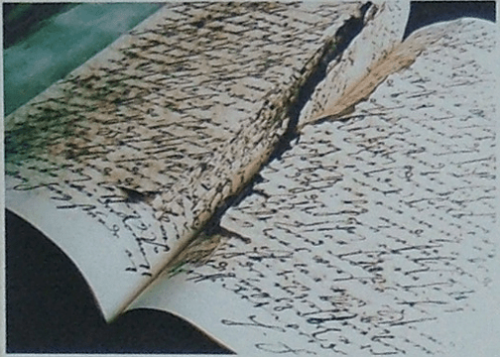

Today’s pens combine pen and ink into a convenient vessel, ready for instant use. In Austen’s day, pen and ink were separate entities, both of which needed to be available in order for writing to be possible.

Inks of various compositions and qualities were available in Austen’s time, both home made and purchased. The properties of good ink were widely agreed upon.

The chief requisites for the making of good ink, are:

1. Limpidity. so that it may flow freely from the pen.

2. A deep. uniform and black colour.

3. Durability. so that the letters be not liable to be effaced by age; and

4. It should be divested of any corrosive quality, by which the substance of the paper may be destroyed, or the writing rendered in any illegible.

No ink, however, hitherto used, possesses all these properties; hence several ingenious chemists have been induced to make experiments, in order to render it more perfect.

~The Domestic Encyclopedia

Making Ink

As with many goods, ink was often made at home. Recipes for ink were widely available in domestic encyclopedias and household management books and utilized items easily available from local sources including the garden, the grocer, and the apothecary. Some of these items might not be familiar so here’s a quick glossary of terms from the recipes.

Glossary of Terms

Allepo galls: galls produced by an Allepo Oak tree

Alum: astringent compound of aluminum and potassium sulphate; mordant that fixes dyes in a material

Avignon berry: also French berry, Persian berry. The fruit of the Avignon bukthorn

Blue galls: high quality galls

Blue Vitriol: copper sulphate; antimicrobial and fungicide

Ceruse: white lead

Cream of tartar: potassium bitartrate; byproduct of wine fermentation

Flake White: pigment made form white lead

Galls: an oak tree’s protective reaction to wasp eggs deposited under its bark.

Green Copperas, also green vitriol, also vitriol of iron, iron sulfate: ferrous sulfate; a mordant that fixes dyes in a material

Gum Arabic: a natural gum originally consisting of the hardened sap of two species of the Acacia tree; thickening and binding agent

Gum tragacanth, also gum adragant: viscous, odorless, tasteless, water-soluble obtained from sap that is drained from the root of certain legume (commonly called goat’s thorn and loco weed) and dried; binding agent especially suitable for powders

Gum water: A remedy for coughs and stomach complaints, made from boiling water and gum arabic.

Indigo: a species of plant used to create blue dye and the dye created from it.

litharge of gold: led oxide mixed with red led

Logwood, also Bloodwood: a species of flowering tree in the legume family, native to Central America and West Indies, produces dyes ranging from red-purples to blues.

Oil of Vitriol: concentrated sulfuric acid

Quick lime: also burnt lime; caustic, alkaline calcium oxide compound

Red Orpiment: deep-colored, orange-yellow arsenic sulfide mineral used in red pigments

Verdigris: poisonous, blue-green copper-based pigment from the patina on copper

Vitriolic acid: sulfuric acid

Recipes for black ink

Though admittedly imperfect, the two primary forms of black ink available were carbon black ink and iron gall ink. The former consisted of soot or lamp black that would then be blended with a weak gum or glue solution. Iron gall ink came from iron galls that were soaked with water, mixed with iron salts and fermented. The acidity of the ink bound it strongly to the paper, making forgery very difficult, but the same property also made it rather destructive to the paper.

Recipe for carbon black ink:

To make Indian Ink . Put six lighted wicks into a dish of oil ; bang an iron or tin concave cover over it so as to receive all the smoke ; when there is a sufficient quantity of soot settled to the then take it off gently with a feather upon a sheet of paper , and mix it up with gum tragacanth to a proper consistence in small portions ,. N. B. The clearest oil makes the finest soot , consequently the best ink

~The Domestic Encyclopedia

Iron gall ink was far more involved to make. In general, it was madeof four main ingredients:. Galls, an acidic solvent, such as beer or wine, (or perhaps more interestingly, allowing mold to grow on the gall nuts as they soak help produce gallic acid.) The acid improved the ink’s color. Ferrous sulfate which would react with gallic acid to produce a blue-black iron-tannin complex. Finally gum arabic which would keep pigment particles in suspension, bind ink to the writing surface, and improve the ink’s flow.

Despite its capacity to eat away the paper it was used on, Iron gall ink could be made very thin, so it would remain on the pen nib a long time, enabling the hairline stroke beautiful pennmanship required.

Recipes for Iron Gall Ink:

607 . To make Ink . To three quarts of water add three pints of white wine vinegar ; fifteen ounces of blue galls slightly bruised ; let these stand near a fire six days ; then put in six ounces of green copperas , and seven ounces of gum arabic finely pounded ; permit the whole to remain near a fire six days more , and be frequently stirred up ; strain the liquor through a fine cloth , and bottle it up for use . Remark . The vinegar improves the colour of the ink , but it has the troublesome effect of destroy ing the pen very quickly . Pronet says , the best ink is made by digesting the infusion of galls in pure water , upon iron . That process certainly makes a very good ink . The proper proportion of gum is of course added .

~New Family receipt book

187. To make good Black Ink . TAKE eight ounces of Aleppo galls in coarse powder , four ounces of logwood in thin chips , four ounces of sulphate of iron , ( green copperas ) three ounces of gum arabic in powder , one ounce of sulphate of copper , ( blue vitriol ) and one ounce of sugar candy . Boil the galls and logwood together in twelve pounds of water for one hour , or till half the liquid has been evaporated . Strain the decoction through a hair sieve , or linen cloth , and then add the other ingredients . Stir the mixture till the whole is dissolved , more especially the gum , after which leave it to subside for twenty – four hours . Then decant the ink , and preserve it in bottles of glass or stoneware, well corked .

~Manual of Useful Knowledge

Ink was sometimes made in a convenient powdered form. As such it was easier to store and could be made up fresh when needed:

Recipe for powdered ink:

Ink powder is prepared chiefly from the acid salt of galls, which may be obtained by the following process: Take two ounces of pulverized galls, infuse them in twelve ounces of rain or river-water; expose the for a few days to a warm temperature, and stir it occasionally: after having extracted the coloring matter, fiitre the solution. and suffer it to stand in the open air for several weeks, in a vessel slightly covered. A sediment will then be gradually formed; which, after removing the mouldy skin from the topof the liquor, should be carefully collected. Hot water is next poured on this sediment. when it is again filtered and evaporated to dryness: thus, a grey crystalline salt will be produced, that is the essential basis of black ink and which may be still more purified by repeated solution, filtration, and evaporation.

If one drachm of this salt of galls be triturated with an equal quantity of the purest vitriol of iron, and about twenty grains of perfectly dry gum-arabic, a composition will be obtained which, on adding a proportionate quantity of warm water, instantly affords an excellent black ink.

~Domestic Encyclopedia

Next week we’ll look at some fun colored inks. See you then!

Would you have been the sort to make your own ink, or would you have bought it? Tell me in the comments.

Find more posts on ink here.

Find more on the art of writing here.

References

Bugbee, Lindsey. Iron Gall Ink: A Timeless Favorite. The Postman Knocks. August 3,2021. Accessed March 3, 3023. https://thepostmansknock.com/iron-gall-ink-a-timeless-favorite/

Gupta, Anisha. The Ins & Outs of Iron Gall Ink. American Philosophical Society. February 25, 2021. Accessed March 7, 2023. https://www.amphilsoc.org/blog/ins-outs-iron-gall-ink

Hurford, Robert. Handwriting in the Time of Jane Austen. PERSUASIONS ON-LINE V.30, NO.1 (Winter 2009). Accessed 11/28/22. https://jasna.org/persuasions/on-line/vol30no1/hurford.html

Kane, Katheryn. Ink-Regency Writing Fluid. The Regency Redingote. September 18, 2009. Accessed December 12, 2022. https://regencyredingote.wordpress.com/2009/09/18/ink-regency-writing-fluid/

Pybus, William. A Manual of Useful Knowledge. Printed for the author by William Rawson: London 1810.

The New Family Receipt book. Squire and Warwick:London. 1811.

Willich, A. F. M. and Cooper, Thomas. The Domestic Encyclopedia. Abraham Small: Philadelphia. 1821.

I might have been tempted to try in my youth but I certainly wouldn’t have made my own ink nowadays! I was gifted with an expensive fountain pen while at school and loved using different inks. I preferred black to blue but occasionally used green. I found I wrote so much neater than with a biro.

I haven’t heard of many of the ingredients mentioned and some sound definitely dangerous!

I make inks from medieval recipes, for my scroll work in the Society for Creative Anachronism. I taught many classes in this historical re-enaction group, from quill-cutting to ink-making to pigment mixing. None of the ingredients are toxic, unless one is inclined to drink a tankard of the stuff. Otherwise, the ingredients are safe enough to let children make their own inks and pigments. I’ve not yet made any inks from the Regency period, but the recipes sound familiar. I’d love to meet others interested in the scribal arts.

Pingback:In Her Own Hand - Random Bits of Fascination